English

日本語

株式会社金剛コルメット製作所のサイト

Our work

| 1 White metal alloy. | |

|

The white metal alloy makes from tin, antimony, copper and guest element which dissolved in the component ratio stipulated by the standard. The alloy will be poured into the mold to form ingots. |

| 2 Back metal (Base metal) | |

|

It is not possible to make a plane bearing with only the white metal because the white metal is soft and deformable. Therefore a plane bearing should be lining the white metal on the back metal which has strong strength like the iron. The back metal is procured from materials manufacturer, and it will be subjected to heat treatment for dehydrogenation and thermal refining. |

|

In the case of repair (replacing white metal), workflow is as follows that removing current white metal by heating with a burner, shotblasting, decarbonizing (gray cast iron only), plating with tin, and then casting with white metal. |

| 3 Preprocessing for lining | |

|

The back metal will be machined it to mold its part for lining with white metal under the described dimensions. (We call this Preprocessing) Then, in order to improve the adhesion between the back metal and the white metal, it will be shotblasting and decarburizing (gray cast iron only). |

| 4 Tin-plating | |

|

In order to improve the adhesion of the white metal, the back metal should be plated with tin. It will be done by immersing the back metal into the molten tin. |

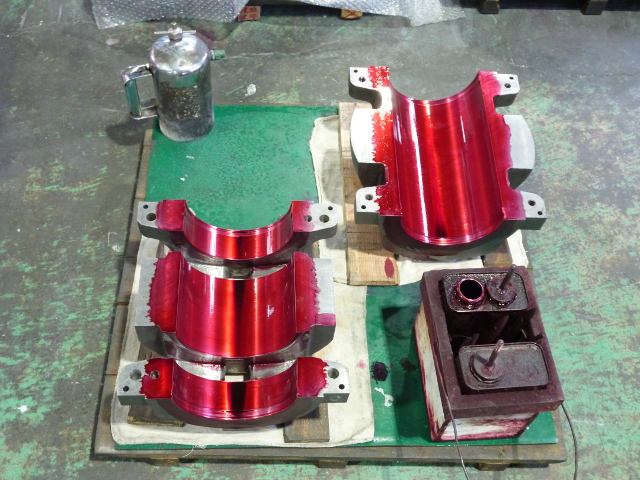

| 5 Casting the white metal | |

|

The back metal will attach to the centrifugal casting machine, and pouring the white metal in while rotating it, so it will be welded with the white metal by cooling it. Such as the white metal amount of pouring in and the cooling procedure at this time, they are our own know-how. |

| 6 Inspection for the adhesion | |

mod.jpg)

|

After casting the white metal, raw bearing will be processed rough-machining. After rough-machining, it will be inspected to verify that the white metal is adherent well on the back metal. (We call this intermediate inspection.) A typical inspection method is staining penetrant inspection (phot lower left) and ultrasonic inspection (photo lower right). |

|

|

| 7 Machining process | |

| It will be machined to dimensions exactly according to the drawings by lathe, milling machine and machining center. | |

|

|

|

|

|

|

| 8 Hand finishing |

|

It will be processed the part which can not be machined to wrap up the bearing by hand finishing. |

| 9 Inspection | |

|

It will be measured to verify that it has been processed with the drawings exactly, and it will be inspected to make sure the white metal will not have any defects or not by the dyeing penetrant inspection and ultrasonic inspection. When it will be passed all inspections, it will be shipped after washing, coated with anti-rust oil and packed. |

|

|

| 10 Quality management of the white metal | |

|

At the time of creating white metal alloy, also it will be made the test piece in addition to the ingots for the componential analysis such as the left photo every 1 lot (approximately 200 kg). |

|

The test piece will be dissolved with chemicals, and analyzed by ICP-AES to make sure the component ratio stipulated by the standard. When analysis result will pass, it can be used as the white metal alloy for the bearing. |

Ingot of white metal

ICP-AES : Inductively Coupled Plasma – Atomic Emission Spectrometry